Related content

REMAS A.S.

MODULAR MILLS

allowing for variable speeds and media within each unit, are key for efficient tile production grinding. Advanced electronics enhance this process.

REMAS provides customized, single-line mill solutions tailored to client needs, enhancing grinding outcomes. Given that mills are major energy consumers in tile production, their optimization significantly reduces costs.

BATCH MILLS

Batch Mills are practical and user-friendly for grinding, providing operational flexibility and consistent slip production.

REMAS creates Batch Mills with volumes up to 68,000lt, capable of handling around 40 tons of raw material. Their specially-designed software and adjustable $time/speed $settings lead to up to 14% energy savings and cost reduction in grinding compared to traditional batch milling.

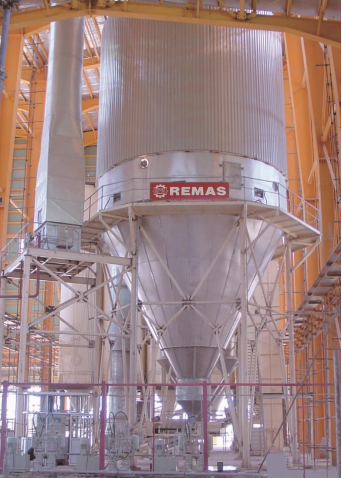

SPRAY DRYERS

Drying the ceramics suspension is the last stage of body preparation. Obtaining and maintaning constant humidity and optimal granule geometry for the granules is extremely cruical.

REMAS is producing up to 25.000lt/h water evaporation capacity spray dryers for perfect drying.

· Lower energy consumption

· Burners with high efficiency and lower fuel consumption

· High efficient fans ensure the effective air flow of the hot air

· Special design of high quality stainless steel cyclones provide low air pressure loss and maximum efficiency

· High density isolation to keep the loss of heat to a minimum

· Adjustable nozzles and removable lances without stopping the system

· Suitable system designs for different type of fuels suitable for cogeneration

· Different solutions for dedusting system (wet scrubber / bag filter)

Energy consumption efficiency is one of the main necessities to be successfully competitive in the modern market. In line with this, we propose different cogeneration system solutions for heat recovery

Company Profile

Since its founding in 1966 in Turkey, REMAS has been a global supplier to the ceramics industry, with over 80% of its facilities dedicated to exports across Asia, the Middle East, Europe, and Africa. The company specializes in body preparation equipment like ball mills, continuous and modular mills, spray dryers, and mixers with automated feeding systems.

REMAS offers a wide range of products, including Continuous Ball Mills with volumes up to 200,000 liters and 1,500kW drive units, Modular Mills with 80,000 liters and 500kW drive units, and Batch Mills up to 68,000 liters with 250kW drive units, as well as Spray Dryers capable of evaporating 25,000 liters of water per hour. They use advanced manufacturing techniques to ensure high-quality, durable products.

The company also provides complete systems for ATOMIZER PLANTS and SLURRY PREPARATION PLANTS, catering to the TILE, SANITARYWARE, and TABLEWARE industries, which include fully automatic batching units, blungers, stirrers, sieves, and pumps as peripheral equipment.

1554591360

1554591360

粤公网安备44010502003188

粤公网安备44010502003188